xoee - Plug & Play Transport Control System

Does that sound familiar?

Logistics areas are bursting at the seams, machines and plants are standing still because the material has run out and forklift driver Klaus wanders through the factory with an empty fork, but doesn't know where to start working? Then it is high time to control the internal material flows in order to bring efficiency back into internal transport.

IPOL offers you with the web-based transport control system xoee a unique plug & play solution for this problem. The introduction, configuration and training of the intuitive system takes only one day. The xoee transport control system only requires an internet connection via mobile phone reception or WLAN and otherwise works absolutely independent of infrastructure.

Your benefits at a glance

- Reduction of empty runs in material provision by controlling the transport orders

- Reduction of inventories in production through demand-oriented replenishment and disposal

- Creating transparency about internal transport volumes and processing times

- Ready for immediate use - installation, configuration and training in just one day

- Low investment costs and risk through a flexible rental model that can be terminated monthly

- Xoee is also worthwhile for temporary analysis or interim assignments

- Low requirements to the own IT infrastructure WLAN or UMTS reception are sufficient

- Further use of already existing hardware is usually possible

- Easy to expand and independently configurable

- Robust technology for demanding requirements and environmental conditions

- Low maintenance due to battery lifetimes of up to 3 years

System & Technology

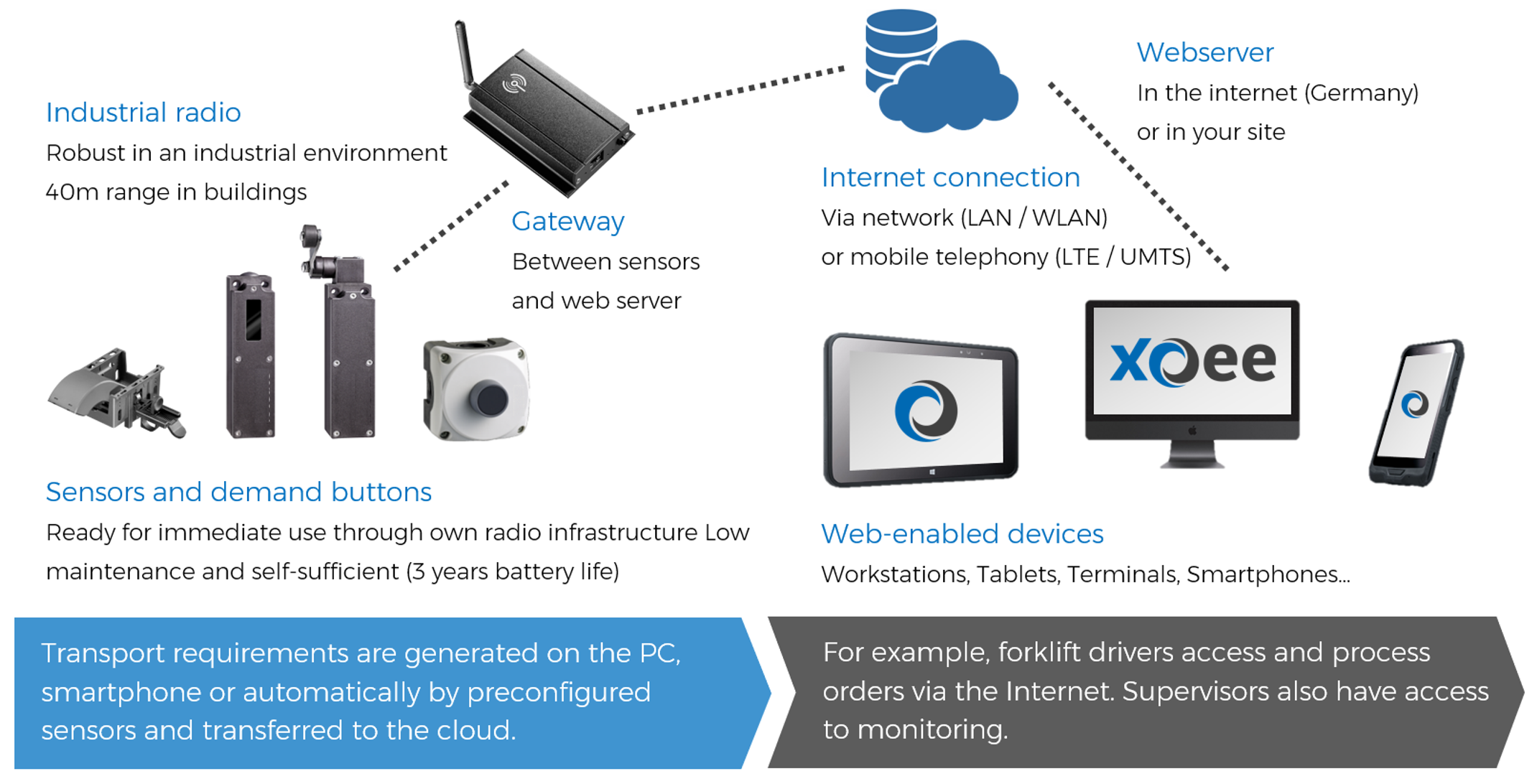

Transfer requirements are generated on the PC, by smartphone, by pressing a wireless button or fully automatically by pre-configured sensors on shelves and machines and transferred to the xoee web server in the cloud.

Transfer requirements are generated on the PC, by smartphone, by pressing a wireless button or fully automatically by pre-configured sensors on shelves and machines and transferred to the xoee web server in the cloud.

Via the Internet forklift drivers, logisticians etc. access and process the orders. Supervisors also have access to the monitoring and dashboard and thus have an overview of your internal material flow at all times - around the clock and accessible from anywhere.

Trigger Transfer Requirements

You have various options for triggering transbord requirements:

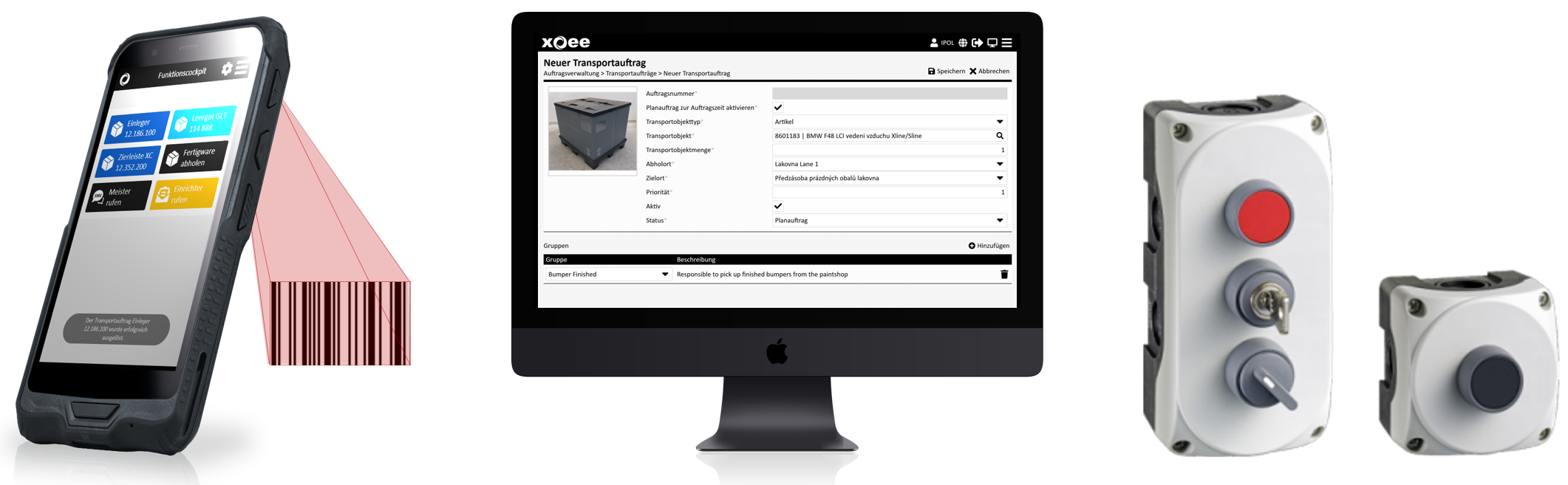

- App or Scan - ideal if a lot of materials are needed at the point of need, which can change frequently

- At the PC workstation - ideal for creating individual or special orders or cyclically recurring orders (e.g. daily waste disposal)

- Operation of a wireless pushbutton - ideal if few materials are required at the point of use that rarely change (e.g. packaging)

- eKanban sensor on the shelf - the shelf rocker is attached to a continuous roller rack and triggers a replenishment order when a box is removed

- Sensors on roller conveyors - If a load carrier rolls past the sensor, it triggers a transport order.

- Sensors on machines - Radio sensors can be mounted directly on machines. There they record the cycle of the plant and can order e.g. new raw material after a given number of cycles.

Editing Transports

Transport orders are processed directly in the web browser. The user is only shown transports for which he is responsible and which are not being processed by other users. The prioritization of the orders is either chronologically or based on container ranges defined in the system.

To make it easier for the driver to find the pick-up and destination location, this can be defined in the plant layout and displayed to the user during transport processing. Due to the language switchability, foreign specialists can also easily find their way around the system.

Keeping an Eye on Processes

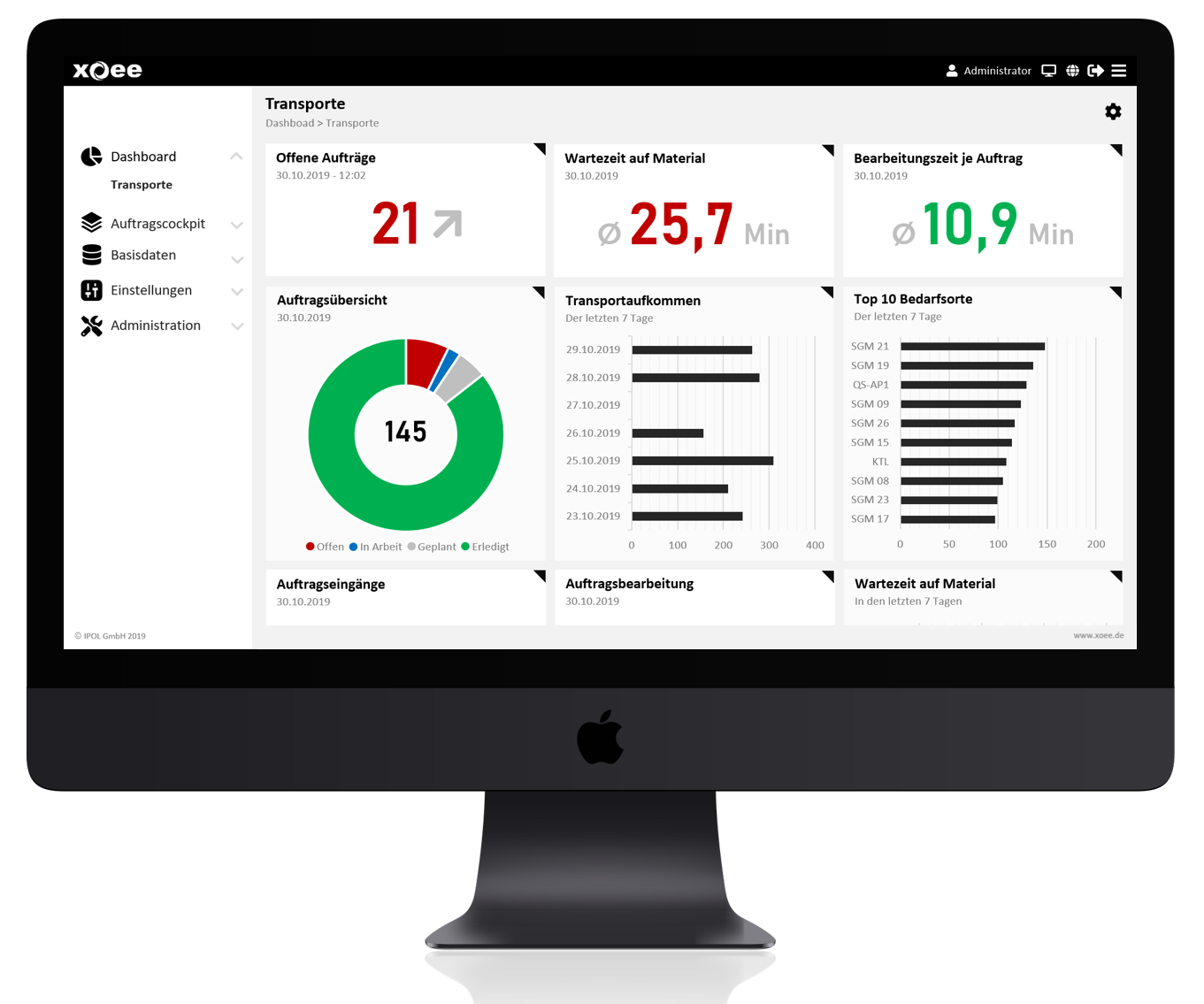

Relevant parameters for assessing the level of service and utilization of internal transport logistics can be monitored live on a dashboard.

All underlying transport data can also be exported in detail as a CSV file for further processing outside xoee.

Full Service is Our Claim

- Project and process consulting for your intralogistics (15 years project experience)

- System and server provisioning, initial configuration

- Installation of the sensor and radio technology at your site

- Provision of mobile end devices incl. mobile phone contract (to a limited extent)

- Administrator and user training directly in your company

- Support and maintenance (remote)

- 48h spare parts service for rented hardware components

- Flexible deployment of the system as a SaaS rental solution that can be terminated on a monthly basis

Contact & Live Demonstration

Make an appointment today for a live demonstration. Book your desired date directly at booking.xoee.de.